We have a strong track record in process optimization and robust process development of peptide molecules. Our team is highly experienced in handling all forms of peptide synthesis viz. solid, solution or hybrid phase peptides at our R and D centers in Hyderabad and Bangalore.

We have a dedicated peptide lab to support peptide synthesis, downstream purification, isolation and lyophilization.

As one of the leading CDMO, we have a state-of-the-art analytical laboratory for impurity characterization and profiling based on spectral methods.

We have one of the largest facilities to manufacture high-throughput synthesis of a wide variety of standard and complex peptides. We can manufacture various types of peptide classes with linear peptides up to 40 AA, conjugates of peptides such as small molecules, lipids, carbohydrates, and PEG. Cost effective LPPS approach for small peptides or linkers. We have expertise in process optimization and robust development for commercial manufacturing.

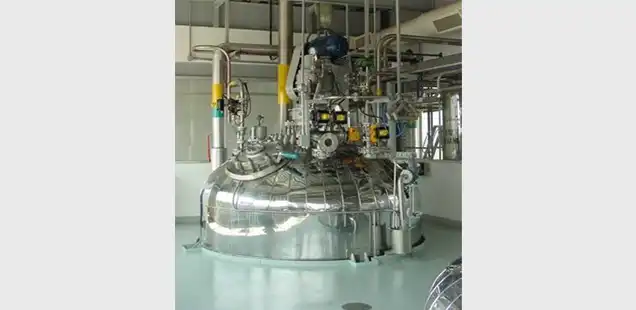

Our advanced technology with modern infrastructure enables us to produce up to 2 kg of linear and branched chain peptides. We provide peptide manufacturing services from our state-of- the-art manufacturing site in Vizag. The site is inspected by major regulatory bodies such as the US FDA, MHRA, and PMDA.

Class of Peptides We Handle

We can handle a wide range of peptides classes such as:

- Linear and branched chain peptides up to 40-mer AA (Natural and unnatural).

- Derivatives of peptides viz., small molecules/ carbohydrate/ PEG

- Peptides with multiple disulfide bridges, head-to-tail cyclization, and side-to-side cyclization

- Stappled, fluorescent and dyes.

- Cysteine rich peptides, lactam bridged peptides.

- Expertise in LPPS, SPPS and hybrid approaches

Lab Infrastructure to Support Peptide Development

Synthesizers

- Cost-effective LPPS approach for small peptides/linkers

- Manual reactors ranging from 100 mL to 10 L capacity (SPPS)

- CS Bio 936S: Automated peptide synthesizer fits for feasibility, optimization studies, pilot studies, and scale-up activities (1 to 5 L).

- CEM Automated Microwave Peptide Synthesizer-2 nos.

Lab -scale purification

- 3 preparative reverse phase HPLCs

- 1 MPLC flash system 250 mL/min pump capacity

- 1 Akta explorer ion exchange chromatography

- 1 Aktaprime plus ion exchange chromatography

- Gel permeation chromatography columns

Isolation techniques

- Crystallization

- Precipitation

- Lyophilization

- Virtis programmable tray of 3 L capacity

- Virtis benchtop of 1.5 L capacity

- Membrane filtration technology

- Tangential Flow Filtration (TFF) 1 kDa, 10kDa, and above

Analytical equipment to support peptide development

- LCMS, GC-MS, LC-Tof, LC Orbitrap, MALDI Tof instruments for characterization

- Multi-angle Light Scattering Detector (MALS)

- Circular Dichroism (CD) analysis for peptides

- 600 MHz nuclear magnetic resonance spectrometry

- Charged Aerosol Detector (CAD) for HPLC

- Amino acid analyzer with post-column derivatization

Clinical Supply Manufacturing

For your clinical supplies and commercial manufacturing needs, we provide peptide manufacturing services from our state-of-the-art manufacturing sites in Visakhapatnam. Both these sites are inspected by major regulatory bodies such as USFDA, MHRA, PMDA etc. Our facilities are equipped with microwave assist technology, liberty pro automatic synthesizers, and fully automated ion exchange purification systems.

Equipments for Peptide Synthesis

- Automated peptide synthesizer (80-160 L)

- Liberty pro peptide synthesizer (25 L)

- Microwave assisted peptide synthesizer

- Hastealloy ANFDs of 1m2 capacity for closed loop filtration operations

- Tangential flow filtration

- Separate peptide block (PB – 16) dedicated to peptides & polymers

Peptide Purification and Isolation

- Preparative RP-HPLC (150 to 600 mm diameter column, flow rate ranging from 3.3 to 20 LPH) with PAT blending technology.

- Fully automated ion exchange resin systems

- Freeze dryer – 100 L capacity (tray)

- Class 100K clean room area with Lyophilizers

Impurity Profiling and Characterization

- LCMS, GC-MS, LC-Tof, LC Orbitrap, MALDI Tof instruments for characterization

- Multi-angle Light Scattering (MALS) detector

- Circular Dichroism (CD) analysis for peptides

- 600 MHz nuclear magnetic resonance spectrometry

- Charged Aerosol Detector (CAD) for HPLC

- Amino acid analyzer with post-column derivatization

Why Aurigene Peptide Development and Manufacturing Services?

Extensive knowledge in developing & manufacturing hundreds of complex pharmaceutical products

Seamless integration from discovery to manufacturing

Capabilities across a wide range of peptide molecules

Large manufacturing capacities with automatic synthesizers

Rethink processes to ensure better quality in shorter timelines

Apply new science and technologies, to reduce costs or risk and add innovation

Connect with our scientific experts for your drug discovery, development, and manufacturing needs

We understand that clear communication is essential to successful collaborations, and that's why we have a dedicated team that is always ready to help you. Whether you have questions about our services, want to discuss a potential partnership, or simply want to learn more about our company, we're here to help.

Our team of experts is dedicated to providing personalised solutions tailored to your unique needs. So, please don't hesitate to reach out to us. We look forward to hearing from you and helping you achieve your business goals.

Learning Resources

NOVEMBER 16, 2023

The importance of business continuity planning in CRDMO industry

Both natural and unnatural catastrophic events inflict negative consequences due to the ever-increasing interconnectedness of the global economy. Those consequences are certain to last for longer duration. e.g.; The Covid-19 pandemic is still having a negative impact on the global economy. Maintaining continuity is critical for all businesses, but perhaps no othe...

Read More

Peptide Development and Manufacturing

Peptides are short chains of amino acids that are linked by peptide bonds. Several peptides linked together are called polypeptides. A protein contains one or more polypeptides. Therefore, proteins are long chains of amino acids held together by peptide bonds....

Read More

cGMP Development and Manufacturing Services

Aurigene Pharmaceutical Services has a legacy of +20 years in developing and manufacturing compounds under cGMP. Our manufacturing plants are spread across 3 continents with facilities in India, UK, and Mexico. ...

Read More

Expediting early development through innovative precision capsule filling technology

Introduction: Any new chemical entity (NCE) needs to undergo various stages of development such as preclinical and clinical trials before drug product is approved by regulatory agencies and available for patient. Formulations developed during early phases are simple formulations to enable phase appropriate studies like screening, dose ranging, toxicological and d...

Read MoreAugust 28, 2020

Revisiting the reaction of b-chloroacroleins with 2-aminophenol: a new observation

The reaction of b-chloroacrolein with 1 equiv of 2-aminophenol in DMF proceeds smoothly to afford 11-hydroxy derivative of chromenoquinoline in good yield. This single pot method allows for a rapid access to a variety of chromenoquinolines or oxepinoquinolines depending on the nature of b-chloroacrolein used. The structures were established by spectroscopic data ...

Read More-

January 31, 2025

Development and assessment of a Bcs class II - SGLT2 (Sodium Glucose Cotransporter 2) inhibitor drug in the form of solid lipid Nanoparticles by selecting different lipids, co-surfactants, and manufacturing techniques

Drug Delivery System (DDS) has been used successfully in the past few decades to cure illnesses and enhance health because of its improved systemic circulation and ability to regulate the drug's pharmacological action. As pharmacology and pharmacokinetics advanced, the idea of controlled release emerged, demonstrating the significance of drug release in assessing...

Read More -

January 31, 2025

Development of novel paullone-based PROTACs as anticancer agents

Proteolysis-targeting chimera (PROTACs) represents a promising modality that has gained significant attention for cancer treatment. Using PROTAC technology, we synthesized novel structurally modified paullone-based PROTACs using Cereblon (CRBN) and Von Hippel–Lindau (VHL) E3 ligands....

Read More -

March 13, 2025

Development and verification of RP-HPLC method for the quantitative determination of Decitabine in tablet dosage formulation

Decitabine is an anti-cancer chemotherapy drug. This article describes method development and method verification of Assay of Decitabine in tablet formulation. A new, precise, rapid, accurate RP-HPLC method has been developed for the estimation of Decitabine in pharmaceutical tablets dosage form. After optimization the good chromatographic separation was achieved...

Read More

You are about to leave Aurigene Pharmaceutical Services and affiliates website. Aurigene Pharmaceutical Services assumes no responsibility for the information presented on the external website or any further links from such sites. These links are presented to you only as a convenience, and the inclusion of any link does not imply endorsement by Aurigene Pharmaceutical Services.

If you wish to continue to this external website, click Proceed.

Leaving already?

Don't forget to join us at

CPHI Worldwide 2023.

October 24th-26th, 2023 | Barcelona, Spain

Get ready to accelerate your drug’s journey to the market