Starting with comprehensive preformulation services to commercial manufacturing, we provide a full suite of services for formulations of oral, parenteral, and topical dosage forms. We offer "Fit-for-purpose" formulation development for preclinical and First-in-Human (FIH) studies based on molecule's physicochemical behavior, excipient compatibility studies, and quick screening of excipients.

Our state-of-the-art formulation manufacturing facilities are in Hyderabad and Visakhapatnam and are audited by all major regulatory agencies.

Cross-functional teams such as DMPK, API synthesis, salt screening, toxicology, process engineering, analytical development, and regulatory teams are located in the same campus and work in an integrated manner at each stage of the life cycle of the molecule for efficient and on-time delivery.

Why choose Aurigene Dosage Formulations Development Services?

Fit-for-purpose development strategy

Integrated cross-functional teams such as PK-PD, API synthesis, salt screening, toxicology, process engineering, and analytical development teams

Services across the product lifecycle

USFDA inspected GMP facilities

Other Services

- Formulation Development Injectables

- Formulation Services

- Liquid Oral Dosage Formulation Development Services

- Nasal Dosage Formulation Development Services

- Ophthalmic and Otic Dosage Formulation Development Services

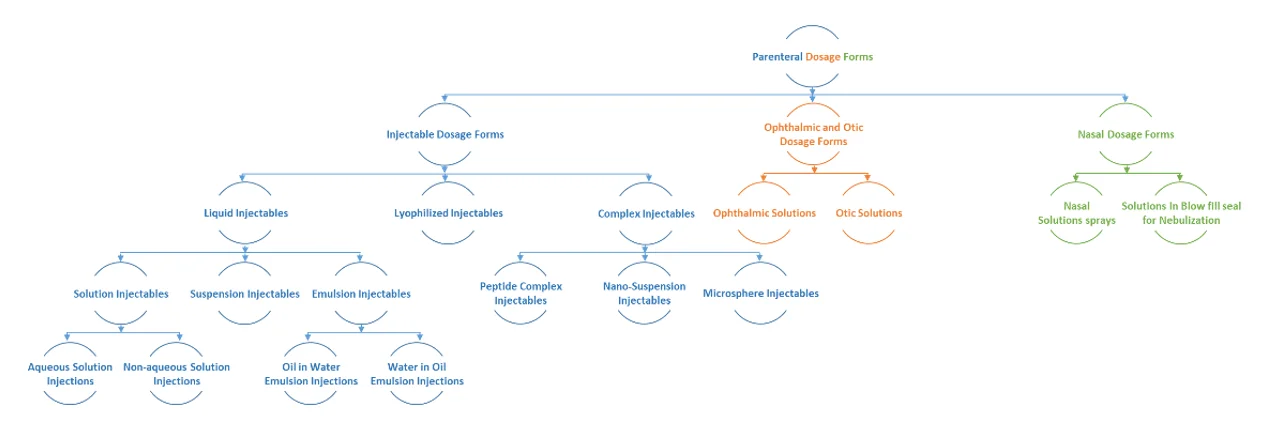

Formulation Development Injectables

Formulation Services

Liquid Oral Dosage Formulation Development Services

Nasal Dosage Formulation Development Services

Ophthalmic and Otic Dosage Formulation Development Services

Oral Solid Dosage Formulation Development Services

Topical Dosage Formulation Development Services

Connect with our scientific experts for your drug discovery, development, and manufacturing needs

We understand that clear communication is essential to successful collaborations, and that's why we have a dedicated team that is always ready to help you. Whether you have questions about our services, want to discuss a potential partnership, or simply want to learn more about our company, we're here to help.

Our team of experts is dedicated to providing personalised solutions tailored to your unique needs. So, please don't hesitate to reach out to us. We look forward to hearing from you and helping you achieve your business goals.

Learning Resources

NOVEMBER 16, 2023

The importance of business continuity planning in CRDMO industry

Both natural and unnatural catastrophic events inflict negative consequences due to the ever-increasing interconnectedness of the global economy. Those consequences are certain to last for longer duration. e.g.; The Covid-19 pandemic is still having a negative impact on the global economy. Maintaining continuity is critical for all businesses, but perhaps no othe...

Read More

Accelerating Drug Discovery Through Innovative Partnerships

Genomics plays a vital role in identifying which gene is associated with a specific disease. A gene called CNOT1 is for example known for it's effect on brain development and for impairing memory and learning. Despite the great promise genomics provides in understanding the disease, genes are not the best drug targets....

Read More

Physiochemical Characterization Services

Backed by our strong chemistry, we enable “Finger-print” protein structure and functional characterization for proteins from naked proteins to hyperglycosylated or derivatized proteins. ...

Read More

Gastro Retentive Dosage Form

Introduction: An orally-available anti-diabetic candidate that simultaneously targets all three key organs of diabetes: Pancreas, Liver and Muscles. This drug targets the two main defects seen in patients with type 2 diabetes: The pancreas by increasing insulin secretion, in a glucose-dependent manner; and the muscles and liver by decreasing the excess production...

Read MoreAugust 28, 2020

An efficient and convenient protocol for the synthesis of tetracyclic isoindolo[1,2-a]quinazoline derivatives

A convenient and one-pot synthesis of tetracyclic isoindolo [1,2-a]quinazoline derivatives via Lewis acid mediated sequential C–N bond formation reactions is reported. This protocol provides a simple and rapid strategy for the synthesis of 12-benzylidene-10,12-dihydroisoindolo[1,2-b]quinazoline derivatives. However, a variety of tetracyclo indole fused quinazol...

Read More-

January 31, 2025

Development and assessment of a Bcs class II - SGLT2 (Sodium Glucose Cotransporter 2) inhibitor drug in the form of solid lipid Nanoparticles by selecting different lipids, co-surfactants, and manufacturing techniques

Drug Delivery System (DDS) has been used successfully in the past few decades to cure illnesses and enhance health because of its improved systemic circulation and ability to regulate the drug's pharmacological action. As pharmacology and pharmacokinetics advanced, the idea of controlled release emerged, demonstrating the significance of drug release in assessing...

Read More -

January 31, 2025

Development of novel paullone-based PROTACs as anticancer agents

Proteolysis-targeting chimera (PROTACs) represents a promising modality that has gained significant attention for cancer treatment. Using PROTAC technology, we synthesized novel structurally modified paullone-based PROTACs using Cereblon (CRBN) and Von Hippel–Lindau (VHL) E3 ligands....

Read More -

March 13, 2025

Development and verification of RP-HPLC method for the quantitative determination of Decitabine in tablet dosage formulation

Decitabine is an anti-cancer chemotherapy drug. This article describes method development and method verification of Assay of Decitabine in tablet formulation. A new, precise, rapid, accurate RP-HPLC method has been developed for the estimation of Decitabine in pharmaceutical tablets dosage form. After optimization the good chromatographic separation was achieved...

Read More

You are about to leave Aurigene Pharmaceutical Services and affiliates website. Aurigene Pharmaceutical Services assumes no responsibility for the information presented on the external website or any further links from such sites. These links are presented to you only as a convenience, and the inclusion of any link does not imply endorsement by Aurigene Pharmaceutical Services.

If you wish to continue to this external website, click Proceed.

Leaving already?

Don't forget to join us at

CPHI Worldwide 2023.

October 24th-26th, 2023 | Barcelona, Spain

Get ready to accelerate your drug’s journey to the market