We have 15+ years of experience with Methoxy polyethylene glycol (mPEG) and activated mPEG development and manufacturing. We perform mPEG development at our R&D center in Hyderabad. Our team has extensive experience in synthesis, analysis, purification and troubleshooting of mPEG derivatives, have technical capabilities in synthetic route design to incorporate various activating groups, and help customize products as per end applications.

Aurigene is a leading manufacturer and supplier of mPEGs and activated mPEGs, which are used for the conjugation of proteins, antibody fragments, and peptides. With our GMP manufacturing capabilities and backward integration to highly pure methoxy PEG-OH, we guarantee the quality and security of the supplies of our activated mPEG products.

As a leading CDMO, we understand customer needs and customize our products to meet those requirements. We currently serve multiple customers across products such as diagnostic players, other mPEG suppliers, and big pharma using mPEG for advanced therapeutics. In addition, our backward integration of key raw materials ensures a sustainable quality of the final activated mPEG throughout manufacturing success.

We have technical capabilities in synthetic route design to incorporate the activating group and help customize products as per end applications. Our centers at Hyderabad and Mirfield are equipped with advanced instruments to enable the scale-up of activated mPEG production up to 90 kg per batch.

Successful custom PEGylation depends on optimizing key factors such as the site of PEGylation, chain length, and mPEG linkers. Finding the ideal mPEG often requires testing multiple activated mPEGs at different chain lengths. We offer a range of activated linear mPEGs to enable our customers to find the ideal mPEG for conjugation of the required quality, with high levels of activation, narrow polydispersity, and low diol content.

Backward Integration of mPEG Alcohol

mPEG-OH is the key raw material for the synthesis of activated PEGs. Our backward integration of key raw materials makes it possible to ensure a sustainable quality of the final activated mPEG throughout the manufacturing process. Our process to make high quality pharmaceutical grade mPEG-OH is patent protected. We manufacture mPEG alcohols in our Cuernavaca, Mexico site.

We support the production of mPEG-OH of molecular weight ranging from2, 5, 10, 20, 30, 40, and 50 kDa.

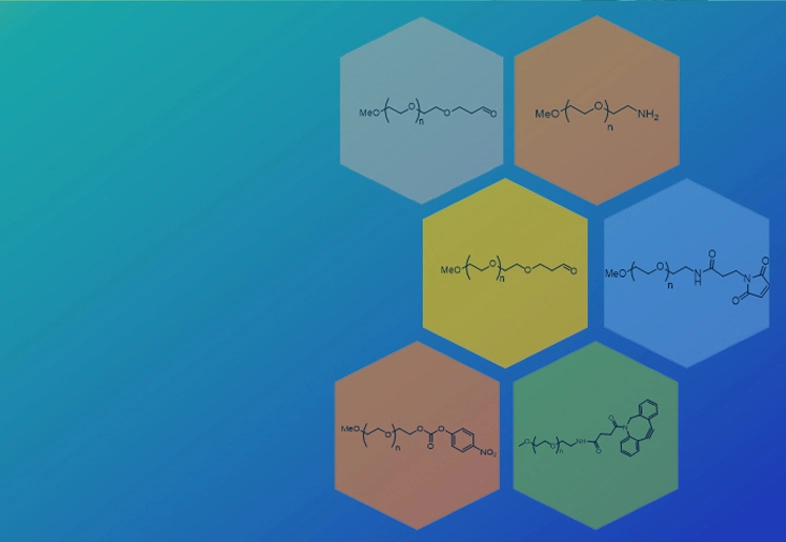

Various Classes of mPEG Derivatives We Can Handle

We are specialists in liner-activated mPEG. Our range of products includes various activating groups such as:

- Methoxy PEG Maleimides (mPEG-Mal)

- Methoxy PEG pNP-Carbonates (p-Nitrophenyl Carbonate PEG)

- Methoxy PEG Propionaldehyde (mPEG-CHO)

- Methoxy PEG Amine (mPEG-NH2)

- Methoxy PEG NHS Ester

- Methoxy PEG Iodoacetamides

- Methoxy PEG Thiols (mPEG-SH)

- Methoxy PEG epoxide

- DBCO-mPEG

We support the production of mPEG derivatives of molecular weight ranging from 2, 5, 10, 20, 30, 40, and 50 kDa.

Activated mPEG Manufacturing at Mirfield and Hyderabad

We help aid our customers with supplies for their development and clinical purposes. We manufacture mPEG derivatives at our Mirfield, UK and Hyderabad, India sites. Key features of our sites are as below:

- Annual capacity ~430 Kg (variable activating groups)

- Clean room manufacturing suite for medium-scale cGMP chemistry (1 - 300 L)

- Temperature range 0 to 150 °C

- Hastelloy hydrogenation or pressure reaction to 20 bar

- Stainless steel filter drier of 100 L capacity, 3 bars

- DCS computer control

- Heat transfer oil for accurate temperature control

Analytical Capabilities

The analysis of large polymeric materials such as PEGs can be challenging. Our analytical lab is equipped with advanced equipment and analytical instruments to determine the quality of our highly pure mPEGs.

In addition, we have a highly experienced analytical team who can characterize the compounds for any required impurity specifications and develop as well as validate such methods.

We perform all critical analytical tests in-house, such as:

- Identification of compounds by NMR

- Analyzing impurities by HPLC

- Testing molecular weight and polydispersity by GPC

- Residual solvent content by GC

- Heavy metal analysis by ICP-OES

- The expected results would be +/- 10% variation

Why Aurigene mPEG Alcohols and Activated mPEG Derivatives Development and Manufacturing Services?

Technical know-how to deliver the most challenging specifications

Experience and legacy of working with big pharma clients

Analytical capabilities

US FDA audited facilities

Backward integration of mPEG alcohol

Other Services

Connect with our scientific experts for your drug discovery, development, and manufacturing needs

We understand that clear communication is essential to successful collaborations, and that's why we have a dedicated team that is always ready to help you. Whether you have questions about our services, want to discuss a potential partnership, or simply want to learn more about our company, we're here to help.

Our team of experts is dedicated to providing personalised solutions tailored to your unique needs. So, please don't hesitate to reach out to us. We look forward to hearing from you and helping you achieve your business goals.

Learning Resources

FEBRUARY 08, 2021

Introduction to PROTAC

PROteolysis TArgeting Chimeras (PROTAC) are a series of hetero-bifunctional molecules that hijack the body’s natural disposal system to initiate selective degradation of the protein of interest (POI). They are generally bifunctional molecules that hijack the Ubiquitin Proteasome System (UPS) to achieve the total degradation of a disease-related target protein. ...

Read More

Peptide Development and Manufacturing

Peptides are short chains of amino acids that are linked by peptide bonds. Several peptides linked together are called polypeptides. A protein contains one or more polypeptides. Therefore, proteins are long chains of amino acids held together by peptide bonds....

Read More

Formulation Development Services

Aurigene Pharmaceutical Services off end-to-end formulation development and manufacturing services fm pr-formulations, clinical development, clinical supplies to commercial manufacturing. ...

Read More

Development of quick quantification method for muscle injury recovery evaluation in thermal injury mice model

Challenges: The evaluation of Evans Blue Dye (EBD) by fluorescence measurements of cryosections of individual muscle sections, and its quantification by auto fluorescence is a laborious and time-consuming process. Study design: Both sham and thermal injury techniques were followed. The evaluation of EBD was done to assess the effectiveness of two compounds in the...

Read MoreAugust 28, 2020

A cascade reaction for the new and direct synthesis of indolofuroquinoxalines

The 7H-indolo[30 ,20 :4,5]furo[2,3-b]quinoxaline derivatives are synthesized directly from methyl 2-(2- chloro-1H-indol-3-yl)-2-oxoacetate or its N-alkyl derivatives under neutral or mildly acidic conditions. This new one-pot methodology was found to be general and greener as it avoids the use of environmentally harmful POCl3 and strong alkali required for the pr...

Read More-

January 31, 2025

Development and assessment of a Bcs class II - SGLT2 (Sodium Glucose Cotransporter 2) inhibitor drug in the form of solid lipid Nanoparticles by selecting different lipids, co-surfactants, and manufacturing techniques

Drug Delivery System (DDS) has been used successfully in the past few decades to cure illnesses and enhance health because of its improved systemic circulation and ability to regulate the drug's pharmacological action. As pharmacology and pharmacokinetics advanced, the idea of controlled release emerged, demonstrating the significance of drug release in assessing...

Read More -

January 31, 2025

Development of novel paullone-based PROTACs as anticancer agents

Proteolysis-targeting chimera (PROTACs) represents a promising modality that has gained significant attention for cancer treatment. Using PROTAC technology, we synthesized novel structurally modified paullone-based PROTACs using Cereblon (CRBN) and Von Hippel–Lindau (VHL) E3 ligands....

Read More -

March 13, 2025

Development and verification of RP-HPLC method for the quantitative determination of Decitabine in tablet dosage formulation

Decitabine is an anti-cancer chemotherapy drug. This article describes method development and method verification of Assay of Decitabine in tablet formulation. A new, precise, rapid, accurate RP-HPLC method has been developed for the estimation of Decitabine in pharmaceutical tablets dosage form. After optimization the good chromatographic separation was achieved...

Read More

You are about to leave Aurigene Pharmaceutical Services and affiliates website. Aurigene Pharmaceutical Services assumes no responsibility for the information presented on the external website or any further links from such sites. These links are presented to you only as a convenience, and the inclusion of any link does not imply endorsement by Aurigene Pharmaceutical Services.

If you wish to continue to this external website, click Proceed.

Leaving already?

Don't forget to join us at

CPHI Worldwide 2023.

October 24th-26th, 2023 | Barcelona, Spain

Get ready to accelerate your drug’s journey to the market