Overview of Injectable Lyophilized Dosage Forms

Injectable lyophilized (freeze-dried) formulations offer enhanced stability and shelf life for sensitive drugs like biologics, vaccines, and antibiotics. These products are reconstituted before use, ensuring precise and effective administration.

What is Lyophilization?

Lyophilization removes water by freezing and sublimation, converting liquid formulations into stable powders without compromising efficacy.

Key Benefits of Injectable Lyophilized Dosage Forms

- Enhanced Stability: Protects drugs from degradation due to temperature, light, or air.

- Improved Shelf Life: Minimizes microbial growth and chemical breakdown.

- Convenient Storage and Transport: Lightweight, often storable at room temperature.

- Precise Dosing and Versatility: Allows flexible dosing upon reconstitution.

- Enhanced Patient Compliance: Easy reconstitution supports accurate and user-friendly administration.

Classification of Lyophilized Injectable Dosage Forms

By Intended Use

- For Solution: These are lyophilized powders intended to be reconstituted into a clear solution suitable for injection.

- For Suspension: These powders are reconstituted into a suspension, where the active ingredient is dispersed in a liquid medium.

By Release Characteristics

- Immediate Release: Upon reconstitution, these formulations release the active ingredient rapidly after administration.

- Extended Release: Formulated to release the active ingredient over an extended period, reducing dosing frequency.

By Formulation Type

- Conventional Lyophilized Powders: Standard formulations requiring reconstitution before injection.

- Depot Formulations: Designed for prolonged drug release, often used in treatments requiring long-term therapy.

Pre-formulation

Pre-formulation is the foundational phase that characterizes the physicochemical properties of the drug substance to guide formulation strategies. Key activities include:

- Solubility and pKa Determination: Assessing aqueous solubility and pKa to inform buffer selection and salt formation.

- Melting Point and Polymorphism Studies: Identifying melting points and polymorphic forms to predict stability and crystallization behavior.

- Thermal Analysis: Using Differential Scanning Calorimetry (DSC) to determine glass transition and collapse temperatures, which are crucial for lyophilization cycle design.

- Excipient Compatibility: Evaluating interactions between the active pharmaceutical ingredient (API) and excipients to prevent instability.

Formulation Development and Optimization

This phase focuses on creating a stable, effective, and manufacturable lyophilized product. Key considerations include:

- Lyophilization Cycle Optimization: Designing freezing and drying conditions to achieve desired cake appearance, reconstitution time, and moisture content.

- Buffer and Excipient Selection: Choosing stabilizers, bulking agents, and tonicity modifiers to enhance stability and solubility.

- Formulation Screening: Conducting stability studies under various conditions to identify optimal formulations.

- Scale-Up Studies: Translating laboratory formulations to pilot and commercial scales while maintaining product quality.

Analytical methods

Analytical method development:

Creating robust methods to accurately measure drug concentration, purity, and stability.

Analytical method validation:

Ensuring methods meet regulatory standards for accuracy, precision, and reliability.

Analytical Method Transfer:

Transferring validated methods across sites to maintain consistency and support scale-up and compliance.

Technology Transfer

Effective technology transfer ensures consistent product quality across different manufacturing sites. Steps include:

- Process Documentation: Providing detailed protocols and specifications.

- Training: Educating receiving sites on processes and quality standards.

- Scale-Up Validation: Conducting trials to confirm that scaled processes yield consistent product quality.

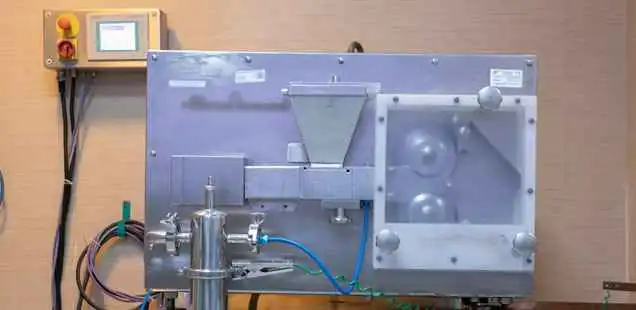

Core Equipment for Lyophilized Injectable Formulation

Lyophilizer Martin Christ Lyophilizer

Freeze-Dry Microscopy LYOSTAT 4.0

Test Parameter

- Identification

- Assay

- Solvent Content

- Water Content

- Related Substances

- Reconstitution Time & Volume

- pH of Reconstituted Solution

- Osmolality of Reconstituted Solution

- Color and Clarity

- Content Uniformity (UOD)

- Particulate Matter

- Bacterial Endotoxin Test (BET)

- Sterility

- Residual solvents

- Elemental impurities

Key Instruments

- HPLC & UPLC’s-UV, PDA, RI, CAD (Make: Agilent / Water’s)

- Particle Size Analyser (Make: Malvern; Model: Sizer 3000)

- Particle Size Analyser (Make:Malvern; Model:Zeta sizer Nano ZSP)

- Polarized Light Microscope (Make: Axio Lab 5; ZEN software)

- Viscometer (Make: Brookfield; Model: DV Next; RV; CP)

- pH meter (Orion Star A211/Thermo)

- UV Visible spectrophotometer [Shimadzu, UV-2600]

- Gas chromatography (Make: Agilent; Model: 8890)

- Osmometer (K-7400S, Knauer GmbH)

- Stability chambers including Photostability chamber [Thermolab Make]

- Volumetric and Coulometric KF Auto titrator [Metrohm make]

- FT-IR (Make: Shimadzu)

- Dissolution apparatus (Electrolab; Trust-E14, Trust E-08, with iDisso)

Why Choose Us

Innovation-Driven Approach

Advanced Technology Platforms

Proven track record in injectable drug development

Integrated, end-to-end Solutions

Unmatched quality & regulatory expertise

Customized, scalable Manufacturing

Expedited delivery service

Strategic collaboration & transparency

Connect with our scientific experts for your drug discovery, development, and manufacturing needs

We understand that clear communication is essential to successful collaborations, and that's why we have a dedicated team that is always ready to help you. Whether you have questions about our services, want to discuss a potential partnership, or simply want to learn more about our company, we're here to help.

Our team of experts is dedicated to providing personalised solutions tailored to your unique needs. So, please don't hesitate to reach out to us. We look forward to hearing from you and helping you achieve your business goals.

You are about to leave Aurigene Pharmaceutical Services and affiliates website. Aurigene Pharmaceutical Services assumes no responsibility for the information presented on the external website or any further links from such sites. These links are presented to you only as a convenience, and the inclusion of any link does not imply endorsement by Aurigene Pharmaceutical Services.

If you wish to continue to this external website, click Proceed.

Leaving already?

Don't forget to join us at

CPHI Worldwide 2023.

October 24th-26th, 2023 | Barcelona, Spain

Get ready to accelerate your drug’s journey to the market