Route Scouting is an essential step in the chemical development process for the manufacturing of a drug substance. When the compound passes the preclinical stage and reaches the development phase, the route of synthesis used in the drug discovery phase may not be feasible or be the optimum route of synthesis for large scale manufacturing.

Process research scientists consider a wide range of factors before establishing the final route of synthesis. Safety, environment, legal, economics, control,and throughput (SELECT) principles are used to scout for the optimum process, covering all aspects for an optimum route.

Factors that determine the most optimum route for chemical Development

Safety is an important factor while designing a route. The factors considered are stability of reaction, toxicity of the raw material used, any toxic gas/waste generated during the reaction or any unstable raw material used in the process.

Environment is the key to sustainability, and process research scientists strive hard to design a green route scouting method to reduce the waste generated, avoid toxic waste, and if the waste can be recycled.

Legal factors are another aspect of process research. Some raw materials such as narcotics or hazardous substances can be restricted, and IP can protect some steps required in the process.

Economic viability determines the steps and raw materials used in the process, minimizing the number of steps, developing telescopic processes, the availability of the raw materials in the domestic market, recovery of solvent, and cost associated with the disposal of the waste generated.

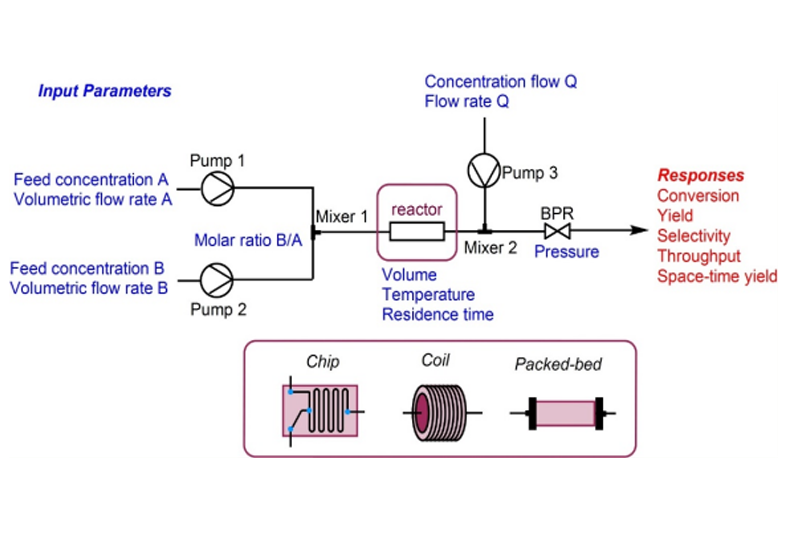

Control related factors affect the deliverability of the project on time, in full, and with the highest purity. Process research scientists study and understand the parameters, flexibility of the process, and how to reduce the impurities.

Throughput factors optimize the yield and consider minimal steps used for purification and isolation.

Latest Posts

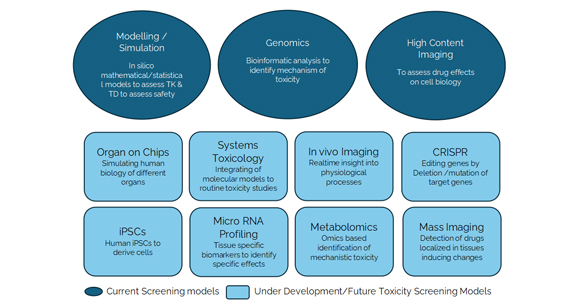

Good practices in non-clinical toxicology assessment to accelerate IND and NDA Submissions

You are about to leave Aurigene Pharmaceutical Services and affiliates website. Aurigene Pharmaceutical Services assumes no responsibility for the information presented on the external website or any further links from such sites. These links are presented to you only as a convenience, and the inclusion of any link does not imply endorsement by Aurigene Pharmaceutical Services.

If you wish to continue to this external website, click Proceed.

Leaving already?

Don't forget to join us at

CPHI Worldwide 2023.

October 24th-26th, 2023 | Barcelona, Spain

Get ready to accelerate your drug’s journey to the market